There are many different solutions for industrial heating: from gas systems (the most traditional and older ones) to biomass systems, from cogeneration solutions (production of thermal and electrical energy in a single device) to heat pumps.

For each solution, then, there are multiple realisations. That is, multiple industrial heating systems, each with specific advantages and ideal applications. But how to choose between one and the other? How do you know which one is best suited to your working environment?

To help you in this choice, in this article we explain the main differences between industrial heating systems.

- Size of the building: is the area of the hall or building very large? Are the ceilings very high?

- Thermal insulation: is it well insulated and does it retain the heat produced or is there significant heat loss?

- Areas to be heated: do you need to heat only certain areas or the whole building indiscriminately?

- Hours/day of operation: for how many hours must the heating be switched on? For short periods of time or 24 hours a day?

Differences between industrial heating systems

We come to the point: here are the main industrial heating systems.

- Underfloor heating. Through coils placed under the floor, a heated fluid flows, carrying the heat and releasing it along the way. Considering that warehouses or industrial buildings are often very high, if you need to heat the whole area evenly while keeping the hot air at a low level, this can be a solution.

- Micro-perforated ducts. At the top of the building, pipes are placed with many small holes from which hot air escapes. As you can easily imagine, the heat loss is high, not to mention that the hot air tends to stay at the top. This solution is not very efficient.

- Wall-mounted hot air splits. Rather than splits, these are individual units, arranged here and there along the walls, consisting of a fan and burner. The burner produces the heat, which the fan then distributes to the room. This can be a good solution in case you need to heat not the whole room but only a few limited areas. However, it is not very environmentally friendly: the air moved by the fan inevitably tends to rise upwards, with a high degree of dispersion.

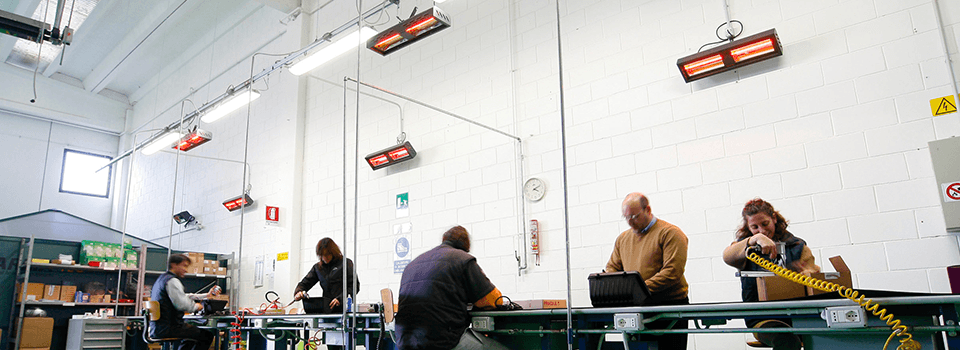

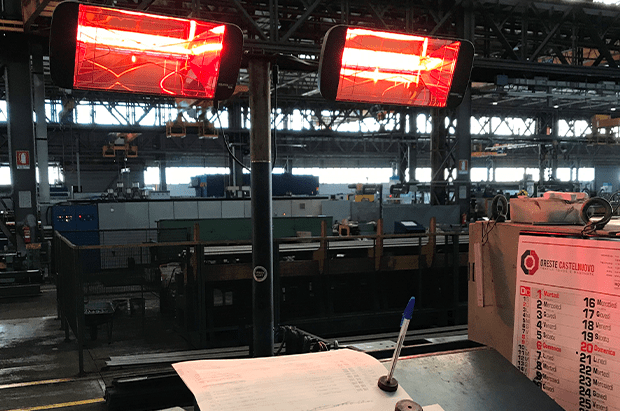

- Infrared systems. Infrared systems make use of heating lamps, which are able to generate immediate and precise heat. Radiation allows objects and people to be heated directly, without heating the air in the medium, which therefore does not stratify and does not cause heat loss.

The advantages of infrared industrial heating

As you may have guessed from analysing the differences between industrial heating systems, the most efficient method at present is the infrared system. All things being equal, infrared industrial heating systems are in fact advantageous in many ways.

With industrial heating systems such as Star Progetti, you eliminate problems such as:

- Heat loss. Infrared lamps heat in a targeted manner, only where it is needed. You can provide a few lamps and position them only where they are needed, e.g. only at certain workstations. With infrared, then, the heat generated comes into direct contact with objects or bodies that are in the vicinity of the lamp, without dispersing the heat into the surrounding environment.

- Moving air and dust. As infrared does not overheat the air in the room, it does not cause any turbulence or lift of dust or other particles. This is particularly advantageous in the industrial environment.

- Noise. Infrared lamps are completely silent: they do not disturb workers or increase the noise produced by machinery.

- Maintenance-free. Star Progetti infrared heating systems are maintenance-free and our bulbs last more than 7000 hours.

- Pre-heating. There is no need to operate the heating system in advance to reach the desired temperature in time, because infrared lamps produce immediate heat. Just one click to switch them on and start enjoying the heat created.

- CO2 emission. Our infrared heaters are more environmentally friendly because they do not emit CO2.

The substantial difference between conventional industrial heating systems and infrared heating systems is therefore in efficiency and cost. No installation or maintenance costs, no heat loss and no pre-heating: this means that you can save up to 70% compared to the costs of conventional industrial heating systems.

Where to install an infrared heating system

Industrial infrared heating systems are ideal for many industrial sectors:

- mechanical

- nautical

- textile

- chemical

- agri-zootechnical

- food

In addition, we realise ATEX solutions that can be safely integrated into industrial production areas with a high explosion risk.